Case Study 2: Footpath Construction

The project involved widening approximately a mile of existing footpath. Installing new edging kerbs, drop crossings for driveways, raising ironwork and replacing where necessary. There were also new bollards, tactile paving areas, traffic islands and ducting for lighting feeds.

In Phase 1 the paths were excavated to formation levels. From the image (above left) you will notice that some sections involved a complete reconstruction whereas others (above right) were simply widened.

Phase 2 entailed kerb edging the paths with 6" x 1" pre cast concrete edging kerbs. There were also some drop crossings for residential driveways, laid in 6" x 5" crossing kerbs.

Type 1 sub base stone was then graded to the paths and rolled. The outer edges were re-graded with recycled top soils, raked and seeded.

Phase 3 entailed laying 20mm size dense base course tarmac to each section of path and rolling. We "hand laid" each section of base because the project was divided into 150 lineal meter sections. This ensured the majority of path remained open to the public during construction. Ironwork was raised and temporary ramping was laid around trip hazards to make safe.

An existing traffic island was widened as a calming measure, on the approach to a roundabout. New ducting was installed to carry lighting feeds to the keep left bollards positioned inside the island.

A new pre-cast traffic island was installed at another location. Ducting was excavated from feeder pillars, across the road and into the island with inspection chambers at direction changes.

Above left: The island was lifted in two sections and laid on a concrete base. The area between the two outer sections was then kerbed with 6" x 5" crossing kerbs.

The paths were surfaced with 6mm size asphalt laid with a small paver.

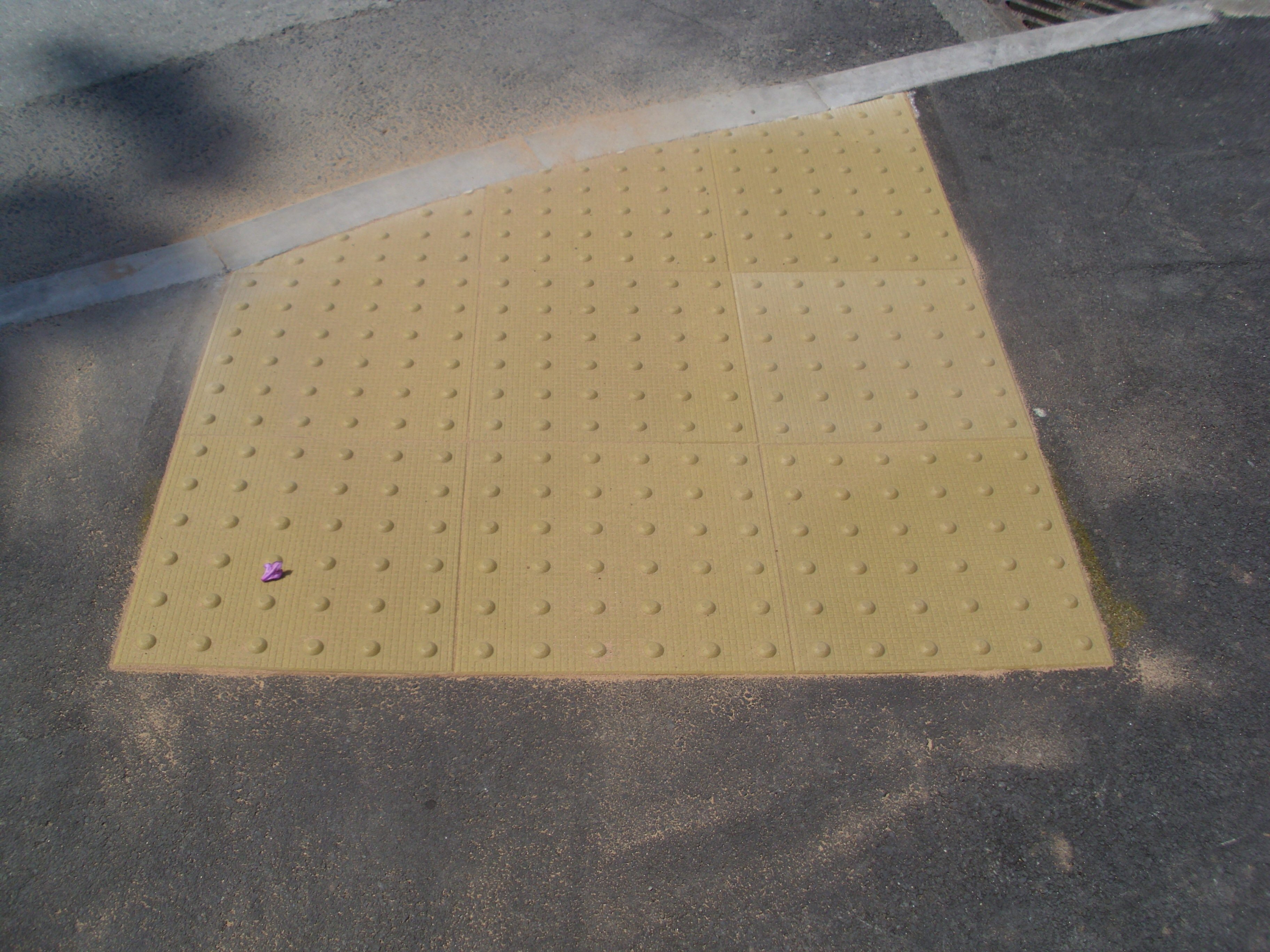

Adhesive tactile paving tiles were resin glued onto the new wearing course to demarcate end and start points and drop crossing points.