Case Study 1: Kerb Laying

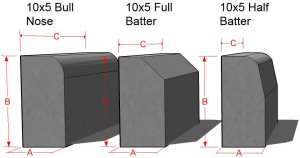

Golden Valley Construction have worked on numerous projects laying Pre-Cast concrete kerbs of all shapes and sizes. This particular project involved laying Half batter kerbs, straight and radius, Dish channel kerbs and Trief Kerbs.

Pre cast kerbs are heavy and we use the latest kerb laying equipment to ensure the health and safety of our workforce. This equipment is actually more productive than traditional methods over prolonged laying periods.

A standard 914mm long Trief kerb weighs approximately 220kgs and again requires specific lifting equipment, we use a scissor lift style device.

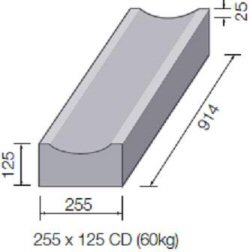

Dish Channel kerbs

are also laid using the above device.

GVC can undertake

kerb laying as a "stand-alone" service. We also offer this service as

part of the full construction of your ground works on a site. GVC have

the equipment and skills to set levels and kerbing lines from

supplied drawings and to client specifications. We have experience

on both industrial & quarry sites, residential driveways and highway

work. GVC have street works licenses to enable them to work on the

highway.

Above: A Mini island kerbed

in HB2 radius and straight kerbs with corner quadrant kerbs.

Above left: Kerbing Radius pins

to pre agreed setting out levels. Above right: Finished radius on a site entrance

splay.

Case Study 2: Footpath Construction :

Case Study 3: Footways & traffic Island

Other Projects: